Pre-Feasibility study plan for Production Vehicle batteries

In Pre-Feasibility study plan for Production Vehicle batteries Technical, Financial, and Economic aspects of the project are explained

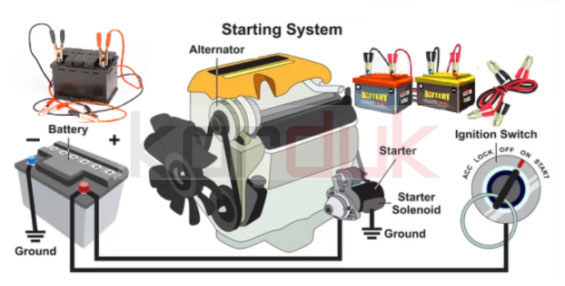

A battery is a device in which electrical energy is stored through chemical reactions so that it can be used when needed. The car battery is a rechargeable power source for starting a vehicle, which sends a voltage to start the engine to provide spark in various internal combustion engines. It also supplies the necessary electricity to the headlights, radio and windshield wipers.

The battery is responsible for supplying energy to the car’s engine from 30 to 70 amps depending on the type of vehicle. So that when the car is started, the car’s electric generator, which is usually the car’s alternator, can generate electricity for the rest of the car’s parts and the engine can start. At such a time, the car usually needs energy equivalent to 13.5 to 14.5 volts.

And if the battery itself tries to power the electrical systems of the engine and transmission controls, the ignition and fuel system, and the audio and climate controls, it will be drained in a short period of time. The four common types of batteries used in cars are: lithium-ion batteries, lead-acid batteries, SLI batteries, and deep-cycle batteries.

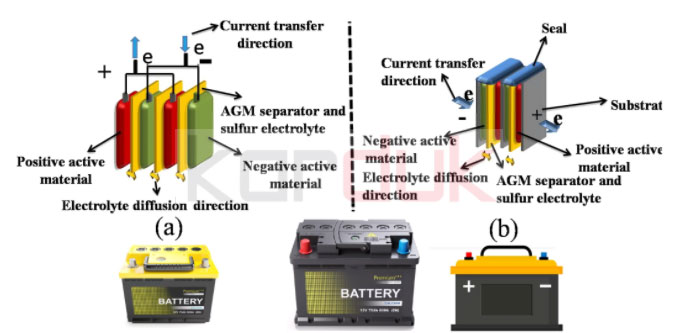

Most vehicles with internal combustion engines use lead-acid batteries. In general, battery design and construction can be classified as follows:

A sealed or wet battery is known as a wet cell battery and requires regular charging with distilled water. Valve Regulated Lead Acid (VRLA). A sealed, high-quality battery, also known as a sealed lead acid (SLA) battery. It does not require refilling and does not spill liquid if tipped over. Lithium-ion batteries used in hybrid vehicles may also have a secondary backup lead acid battery.

The importance of the project

In today’s world, cars have become an important and essential part of people’s lives in different countries, which are constantly becoming more advanced. This level of demand has caused their production in different countries to expand quantitatively and qualitatively, and they are produced in various designs and models.

This need has led to the growth of production technology in industrialized countries due to changing consumption patterns and lifestyles. The development of industrial infrastructure, logistics, and transportation has also been effective in the development of automotive manufacturing, such that automobile production has become one of the largest industrial and trade activities in the world.

The necessity of using a battery in a Vehicle

Car battery is an element that plays a role in starting any type of vehicle. The suitability of the battery capacity and power with the vehicle’s electrical system will result in a good start of the vehicle. When the battery capacity is low, the starting time increases to start the vehicle. Long-term and continuous starting causes overheating of the starter and is likely to lead to starter failure, and if the battery capacity is greater than the vehicle’s requirement, the life of the vehicle’s starting system will be reduced.

If the internal resistance of the battery is within reasonable limits, the current generated during starting will increase as the capacity increases. Today, due to the problems of wet batteries, the use of dry, insulated batteries is expanding. Passenger car and van batteries are usually 12-volt, and heavy-duty and diesel vehicles are 24-volt.

The output of a battery is measured in ampere-hours based on its structure and also in voltage, for example, a 12V and 60AH battery means 12 volts and 60 amps.

Technical Specifications | Pre-Feasibility study plan for Production Vehicle batteries

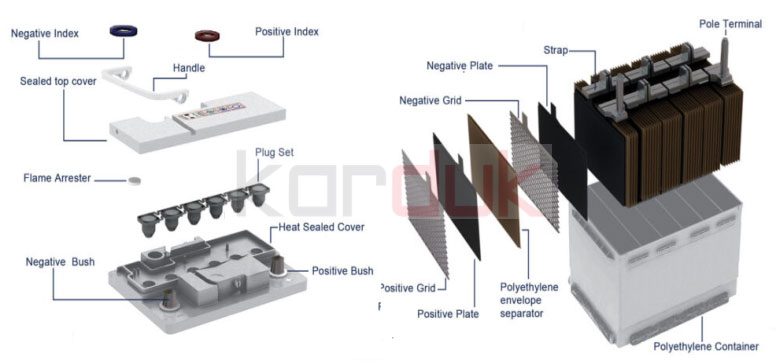

The structure of the vehicle battery system is shown in the figure. The figure below is an example of a six-cell wet cell car battery. Each storage battery cell is made of lead plates that have an alloy grid of sponge lead plates (cathode) and are coated with lead dioxide (anode). The cells are filled with a sulfuric acid solution, which is the electrolyte, to conduct electricity.

Product Classification | Pre-Feasibility study plan for Production Vehicle batteries

Currently, the 8 common types of batteries used in the automotive industry can be listed as follows:

- Flooded lead acid battery (wet cell)

- Silver calcium battery

- Enhanced Flooded Battery (EFB)

- Gel cell battery (dry cell)

- Absorbent Glass Mat (AGM) Battery

- Deep Cycle Battery

- Lithium-ion (Li-Ion) battery

- Nickel Metal Hydride Battery

Production Process| Pre-Feasibility study plan for Production Vehicle batteries

The process of assembling and manufacturing a car battery initially involves preparing the basic raw materials, which vary depending on the type of material that makes up the plates and cells of the car battery. For lead-acid batteries, lead powder is first oxidized, and then a large number of battery grid plates are made suitable for collecting current and storing active materials on parallel plates according to amperage.

Depending on the type of negative or positive plates, active paste materials are placed on them and the manufactured metal networks are processed and prepared, meaning the paste layer deposition process is performed on the produced networks.

And the networks with dried paste and after separation, brushing and connection between the produced sheets, they are ready to enter the assembly section.

During the assembly stage, to prevent short circuits, the positive and negative plates are placed in polyolefin insulating layers and separated from each other. In the process, they are regularly placed inside the battery box cells to form parallel cells.

After establishing the connection, positive and negative polarity, and adjusting the arrangement of the plates, the device connects the ends of the plates’ flags in the C.O.S. device using molten lead.

The battery boxes are punched with a punching machine according to the desired sizes so that the leads of the flagpoles of the plates can be connected to each other through these holes until the electrolyte is ready to enter. The battery is then tested by a testing machine in a voltage range for all types of batteries with voltages of 12 volts.

List of Machinery for Production Battery

Production of light, medium and heavy vehicle batteries in different sizes based on the platform and specific technical specifications. The machinery is designed, manufactured and arranged based on the specifications, capacity and production process. Battery production line machinery consists of various sections as follows:

- PLATE MANUFACTURING MACHINE

- Lead ingot cold cutting machine

- Battery plate baking and drying chamber

- Expanded line of battery plate mesh strips

- Lead oxide ball mill

- Lead oxide filling machine

- Battery lead grid casting machine

- PDC tube battery plate machine

- Battery charger and discharger plate forming machine

- Lead paste mixer machine from 50 to 1000 kg

- Flash dryer oven

- Double-sided paste machine for lead-acid battery plates

- Battery plate cutting machine

- Lead acid battery plate brushing machine

- Continuous plate bending line

- Acidic dilution system

- Battery water cooling circulation system

- Gel mixing machine for batteries

- Industrial coating machine

- Battery assembly line

- Battery plate coating and stacking machine (PE)

- Automatic AGM plate coating and stacking machine

- Fully automatic COS machines

- Semi-automatic intercellular welding machine

- Automatic battery epoxy drying oven machine

- Battery box punching machine

- Screen short circuit testing device

- Intercell automatic battery welding machine

- Battery heat sealing machine

- Battery pole welding machine

- Battery air leak testing device

- Battery marking machine

- Battery charging and discharging system

- Battery plate charging device

- Automatic lead acid battery filling machine

- Acid gel adding device

- Battery heat sealing machine

- Ultrasonic welding machine

- Battery-powered washer and dryer

- HRD testing machine

- Battery packing line

- Battery screen printing machine

- Battery labeling machine

Alternative products

In general, the characteristics of the battery determine which type of battery and capacity the automaker will use in which of its vehicles. Sodium-ion (NIB) and LFP batteries from the lithium-ion (LIB) group may be used for light city cars, motorcycles, and more expensive and efficient batteries such as NMC lithium-ion may be used. But in both internal combustion engine vehicles and electric vehicles, there is no replacement for batteries.

The ISIC code of product | Pre-Feasibility study plan for Production Vehicle batteries

The International Standard Industrial Classification of All Economic Activities (ISIC) is the international reference classification of productive activities. It’s main purpose is to provide a set of activity categories that can be utilized for the collection and reporting of statistics according to such activities. According to the ISIC classification system, According to the ISIC classification, the code (3140) is related to the manufacture of electrical machinery and equipment. The ASIC code of the products of this plan is as follows.

- Carbon-zinc dry batteries : 3140412318

- Lithium batteries and powers 3140412318

- Mercury Oxide Batteries and Power Supplies 3140412310

- Silver Oxide Batteries and Power Supplies 3140412314

- LM starter lead acid battery: 3140512335

- Absorbed lead-acid batteries: 3140512332

Buildings required for the project implementation

The building space required for the production lines, administrative and headquarters departments, according to the site plan and layout of Production plan for Vehicle batteries, is as follows:

- Industrial production area: 4,000 Mr2

- Storage Rooms for Raw Materials and Finished Products 2,500 Mr2

- Mechanical and Electrical facilities 400 Mr2

- Laboratory and R&D department : 150 Mr2

- Office Building and Staff Welfare Areas 300 Mr2

- Security Building: 100 Mr2

Raw materials, auxiliary materials and packaging

The most important raw materials used in the production of various types of automotive batteries are as follows:

- Battery container

- Soft lead 99.8/99

- Lead alloy

- Body

- Sulfuric acid

- Insulating plates

- Pole

- Hydrometer

- Auxiliaries

Introduce Target Market| Pre-Feasibility study plan for Production Vehicle batteries

The target audience for battery consumption is automakers and all car owners whose car batteries have reached the end of their life or whose car batteries are damaged and need to be replaced.

Battery production statistics are directly dependent on the amount of vehicle production and the number of active vehicles in countries and the world.

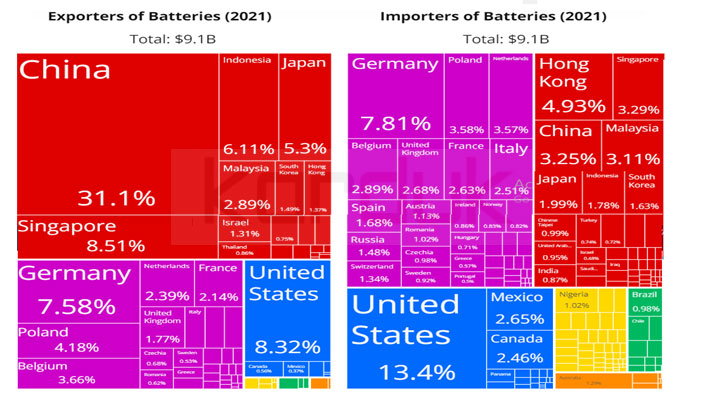

In 2021, batteries were the 382nd most traded product in the world, with trade of $9.1 billion. Between 2020 and 2021, battery exports increased by 8.26% from $8.4 billion to $9.1 billion. Battery trade accounts for 0.043% of total global.

Batteries are part of electrical and electronic machinery. They include primary manganese dioxide cells and battery volumes of less than 300 cc, primary cells, primary batteries, volumes of less than 300 cc and parts of primary cells and silver oxide batteries with volumes of more than 300 cc, and mercury oxide cells with volumes of less than 300 cc and more than 300 cc.

Total battery exports in 2021 The largest battery exporters were China ($2.83 billion), Singapore ($775 million), the United States ($757 million), Germany ($690 million) and Indonesia ($556 million).

Financial Projection| Pre-Feasibility study plan for Production Vehicle batteries

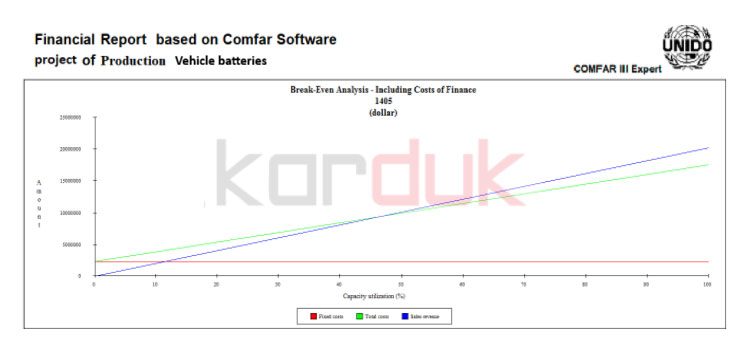

The financial statements and operating costs Production Vehicle batteries show a suitable situation for the project, considering the cost price of the products and the annual profit. Results of the analysis performed by the Comfar software, with a discount rate of 28 %, also show an acceptable situation in terms of financial and economic terms for the base of Production plan for Production Vehicle batteries project.

Summary of study Results

Production calculations show that the proposed production capacity can be increased according to the needs of the domestic market and the country, considering the competitive price of the products The financial statements and operating costs of Production Vehicle batteries show a suitable situation for the project, considering the cost price of the products and the annual profit.

The results of the analyses conducted by Comfar software with a discount rate of 28% also show an acceptable situation in terms of financial and economic terms for Production Vehicle batteries project with a Capacity of 500,000 batteries per year

For more information about the Feasibility Studies of Production Vehicle batteries . you can contact Karduk.INC via WhatsApp, Telegram or E-mail.

Phone: +982166418908

Email: karduuk@gmail.com