Pre-Feasibility study of Production plan for metal Profiles and Pipes

In Pre-Feasibility study of Production plan for metal Profiles and Pipes Technical, Financial, and Economic aspects of the project are explained .

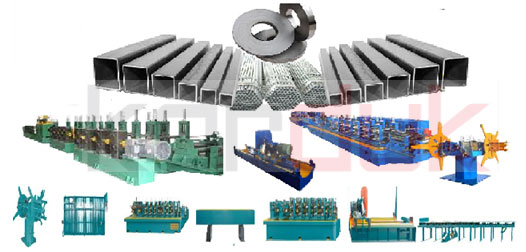

Metal profile means a fixed cross-section in a given length. Metal profiles are produced in two forms, open and closed, with welded seams. Steel pipes and profiles are secondary products of steel sections, similar to metal sheets. In fact, the raw materials for the production of these products are various types of steel sheets in different thicknesses The majority of metal pipes are used in the domestic water supply network.

The importance of the project

The production of various types of metal sections used in the construction industry in all provinces of the country is a necessity, given the importance of its use in civil and building structures. The production of these products is necessary because they have a competitive and developmental advantage and provide a chain of multiple socio-economic values

Technical Specifications | Pre-Feasibility study of Production plan for metal Profiles and Pipes

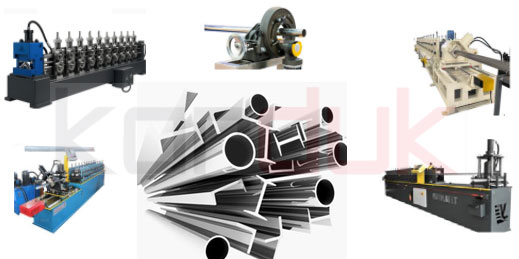

The products studied in this project are the production of galvanized, oil-coated, and black welded steel pipes up to 4 inches in size, which are used in the transportation of liquids and gases in construction, industrial, agricultural, and service facilities, and distribution networks related to the construction of metal skeletons and air tanks.

Product Classification | Pre-Feasibility study of Production plan for metal Profiles and Pipes

In general, products are divided into two groups: welded steel pipes and profiles and seamless metal sections

Welded steel pipes are divided into the following three main groups:

- black and oil-coated galvanized welded steel pipes for water supply

- Black and oil-coated galvanized welded steel pipes for use in gas distribution networks

- Galvanized, black and oil-coated welded steel pipes for special uses

The process and method of manufacturing these three groups of pipes are the same, and what distinguishes them is the nature of the work , performance and external dimensions, and the material and thickness of the sheet used in their production

There are a number of steel profiles that are produced by forming galvanized sheets using the cold rolling method without welding seams and are used to create infrastructure in a variety of dry construction systems. Depending on the type of application of the metal sections, they have several categories for use in the framing of walls and false ceilings and greenhouses.

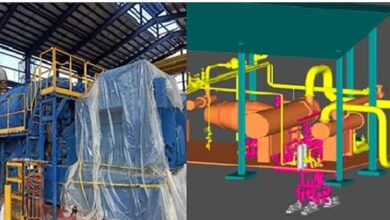

Production Process | Pre-Feasibility study of Production plan for metal Profiles and Pipes

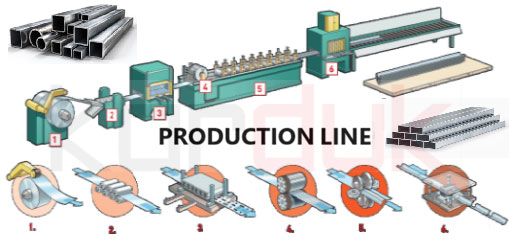

To produce welded pipe and profile, the sheet is formed and rolled by passing through rollers, forming the cross-sectional shape of the unwelded pipe. The two main types of ERW welding are high-frequency induction welding and contact rotation welding.

In high-frequency induction welding, the welding current is transmitted to the material through a work coil in front of the welding point. In linear welding of products, high-frequency induction eliminates contact marks and provides adjustability when changing pipe sizes and consistent weld quality.

In the ERW electric resistance welding method, a tubular steel sheet with flush edges is passed through sliding welding electrodes, during which a high-frequency electric current is passed between the two edges of the steel cylinder to heat the steel so that the adjacent edges are joined together without the use of welding filler materials. and thus create a fusion metal bond. These devices weld and connect the two ends of the pipe together.

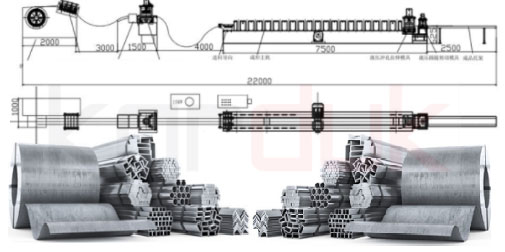

The welded steel sections are passed through a high-pressure roller that helps create a tight weld. The pipe and profile are cut to standard lengths and stacked for further processing. The steel section production process is a continuous process and can have a production capacity of 30 to 300 meters per hour.

In order to produce various types of profiles without welding, studs, runners and metal connections, based on the use of various types of galvanized or colored sheets, the cut roll is cut in the roll forming machine into different longitudinal sections based on the type of application and the forming and perforation dies, and the connections are also produced and made by the press machine

Alternative products

With the advancement of technology in recent years, polyolefin pipes and sections, gray and ductile iron pipes, various types of plastic pipes and profiles, thermoset resins, asbestos-cement pipes, and reinforced concrete products can replace welded steel pipe sections and sections.

The ISIC code of product | Pre-Feasibility study of Production plan for metal Profiles and Pipes

The International Standard Industrial Classification of All Economic Activities (ISIC) is the international reference classification of productive activities. Its main purpose is to provide a set of activity categories that can be utilized for the collection and reporting of statistics according to such activities. According to the ISIC classification system, The two-digit ISIC codes 28 and 27 are for metal products. The ASIC code of the products of this plan is as follows.

- Seamless steel pipe with metal coating (galvanized) 2710512449

- Stainless steel seamless pipe with direct welding 2710512433

- Galvanized steel profile from steel sheet 2710612555

Buildings required for the project implementation

The building space required for the production, administrative and headquarters departments, according to the site plan and layout of Production plan for metal Profiles and Pipes, is as follows:

- Industrial production area: 1,200 Mr2

- Storage Rooms for Raw Materials and Finished Products 600 Mr2

- Mechanical and Electrical facilities 50 Mr2

- Laboratory and R&D department : 50 Mr2

- Office Building and Staff Welfare Areas 200 Mr2

- Security Building: 50 Mr2

Raw materials, auxiliary materials and packaging

The raw materials used in the production of metal pipes and profiles are black and galvanized steel sheets in different thicknesses

Introduce Target Market

Galvanized welded steel pipes and profiles 4 inches and under have the following markets and applications

- Housing (construction) sector: This market accounts for more than 80% of welded steel pipe and profiles consumption

- Gas distribution networks and branches: Pips which are used for installing gas flags and this product is used in gas supply to homes, commercial complexes and buildings

- Industrial and production uses: In the field of various industrial facilities, especially petrochemical industries and industrial facilities, more than 39 percent of the total piping needs are made up of galvanized welded seam pipes.

- The scope of application of pipes as industrial raw materials: Welded seam pipes are used in the supply chain of many industrial activities, such as furniture, chairs, and metal furniture.

- Application in the construction of metal skeletons and air tanks: Welded steel pipes with the desired dimensions, metal pipes constitute a high percentage of the total annual need for metal skeletons and air tanks

Financial Projection| Pre-Feasibility study of Production plan for metal Profiles and Pipes

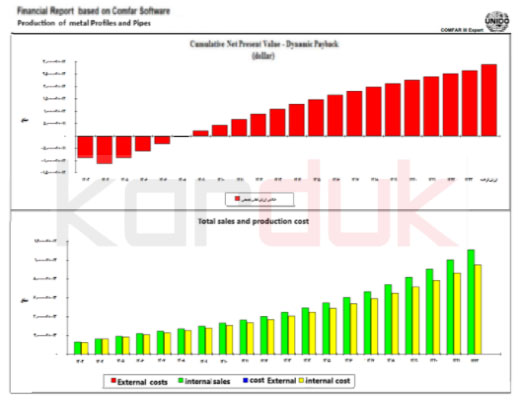

The financial statements and operating costs of re-refining show a suitable situation for the project, considering the cost price of the products and the annual profit. The results of the analysis performed by the Comfar software, with a discount rate of 25%, also show an acceptable situation in terms of financial and economic terms for the base of Production plan for metal Profiles and Pipes project.

Summary of study Results

Production calculations show that the proposed production capacity can be increased according to the needs of the domestic market and the country, considering the competitive price of the products The financial statements and operating costs of Production metal Profiles and Pipes show a suitable situation for the project, considering the cost price of the products and the annual profit.

The results of the analyses conducted by Comfar software with a discount rate of 25% also show an acceptable situation in terms of financial and economic terms for Production plan for metal Profiles and Pipes project with a capacity of 21000 tons per year.

For more information about the Feasibility Studies of Production metal Profiles and Pipes . you can contact Karduk.INC via WhatsApp, Telegram or E-mail.

Phone: +982166418908

Email: karduuk@gmail.com