Pre-Feasibility study of Production of Sanitary Napkin

In Pre-Feasibility study of Production of Sanitary Napkin Technical, Financial, and Economic aspects of the project are explained .

A sanitary napkin is a napkin that looks similar to a baby’s sanitary napkin but is smaller in size. Women use it during their menstrual period to maintain hygiene and prevent blood leakage. It has an adhesive strip on one side that is used to fix it to the cloth. Sanitary napkins today are generally sterilized and are made of synthetic fibers, a cotton layer, and liquid-absorbent materials.

The importance of the project

Using sanitary napkins during menstruation not only helps women maintain personal hygiene, but also prevents the risks of harmful microorganisms growing in the blood. For this reason, this product is manufactured all over the world and constitutes a large part of the disposable sanitary products available in the market.

Technical Specifications| Pre-Feasibility study of Production of Sanitary Napkin

In general, sanitary napkins must have a uniform surface and be free from foreign particles, bad fumes, stains, oil, paint, glue, dirt, and other defects that could harm the sanitary user or reduce their effectiveness. Sanitary napkins are made up of the following elements with the following specifications:

-

Outer layer

This layer is made of non-woven fabrics or lint-free polyethylene mesh film. The use of combined layers consisting of non-woven fabrics and polyethylene mesh film or non-woven fabrics and a distribution/transmission layer is permitted.

-

Middle layer

This layer is used to maintain the shape of the absorbent core and control the passage and leakage of secretions. In most winged sanitary napkins, the adhesive is applied between the outer layer and the pulp and there is no need for a middle layer. In a regular sanitary napkin, the middle layer should cover 90% of the length and surface area of the absorbent core.

-

Absorbing mass

Absorbing mass is made of cellulose combed paper pulp which should meet Standard requirements. It should be free of any smear, oil, paint and external particles.

-

Absorbing powder

In some sanitary napkins absorbing powder or absorbing fibers are applied in order to promote absorbing capacity. Absorbing powder could be mixed with pulp or applied between two pulp layers. Applying absorbing powder with different methods should be performed in a manner that no powder could leak out of napkin surface and the powder should be completely controlled within the absorbing mass.

-

Non-penetrable layer or under layer

This layer is located beneath the absorbing materials in order to prevent the leakage of secretions to bottom of the napkin. It is made of a thin poly ethylene film. It should be soft and flexible and produce no noise during use. This layer should cover whole the length and width of the absorbing material. In anatomic winged napkins, this layer serves as the beneath layer and should have sufficient strength and should be fixed to the bottom layer of absorbing material by a special glue.

-

Glue line

The line should be applied uniformly and should preserve its sticky state until consumption time. In anatomic winged napkins, glue lines should cover at least 40% of the absorbing mass width. In winged napkins, the glue lines should be applied in the beneath surface of the wings. Applying protection layer on the glue lines is necessary. In some single packs, the napkin sticks on the poly ethylene pack from its sticky side and in this case silicane paper could be eliminated.

Product Classification | Pre-Feasibility study of Production of Sanitary Napkin

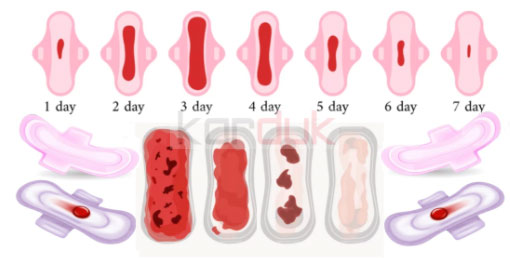

Sanitary pads that are used come in a variety of thicknesses and sizes depending on the time and type of use. These pads can be thin, medium, or thick for use in the first days of a woman’s period. Each of these sanitary pads has different uses and are sold as small and large pads, or night and day pads, and even postpartum pads.

Disposable night pads are wider and longer to prevent leakage; or super sanitary pads have a very high moisture absorption rate and are suitable for use in the first two to three days of menstruation Some of these pads have wings and others do not.

Wings on sanitary pads are small parts that have adhesive and stick to the sides of underwear to prevent blood from leaking onto the body or clothing. Another important feature of pads is their moisture absorption capacity.

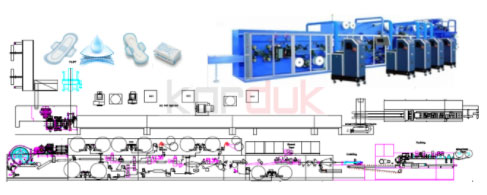

Production Process | Pre-Feasibility study of Production of Sanitary Napkin

In the automatic production process, the layers are placed in the machine in rolls and after transferring and adding absorbent materials and powder to the product in the forming section with a mold, the strips are fixed and shaped using hot melt adhesive. After forming into strips, they are cut, packaged, and the specifications and brand are printed on the package and carton.

Alternative products

Since sanitary napkins are an essential hygiene product, there is no substitute product that has all the characteristics of sanitary napkins. On the other hand, not using sanitary napkins can increase disease and reduce the level of hygiene in the community.

The ISIC code of product | Pre-Feasibility study of Production of Sanitary Napkin

The International Standard Industrial Classification of All Economic Activities (ISIC) is the international reference classification of productive activities. Its main purpose is to provide a set of activity categories that can be utilized for the collection and reporting of statistics according to such activities. According to the ISIC classification system, the ASIC code (2109) is related to the production of various types of sanitary napkins. The ASIC code of the products of this plan is as follows.

- Sanitary napkins 2109412355

Buildings required for the project implementation

The building space required for the production, administrative and headquarters departments, according to the site plan and layout of Production of Sanitary Napkin , is as follows:

- Industrial production area: 300 Mr2

- Storage Rooms for Raw Materials and Finished Products 200 Mr2

- Mechanical and Electrical facilities 30 Mr2

- Laboratory and R&D department : 130 Mr2

- Office Building and Staff Welfare Areas 130 Mr2

- Mechanical and Electrical facilities : 50 Mr2

- Security Building: 30 Mr2

Raw materials, auxiliary materials and packaging

The main raw materials used in the production of sanitary napkins are absorbent layers and powder. The fibers required for these products include natural fibers such as cotton and linen, synthetic fibers such as staple fibers or thermoplastic filaments, and superabsorbent powder. Polypropylene fibers are the most commonly used in these types of pads, and other types of staple and filament fibers such as polyacrylonitrile, polyamide, bicomponent fibers, etc. are also used. After polypropylene, polyethylene terephthalate (polyester) fibers are the most commonly used in these textiles.

Introduce Target Market

Currently, there is an effective demand for continuous use of production sanitary napkins with appropriate added value. The main target market of this project, technically and economically, is at the national level, using modern marketing methods and networks. In the first phase, the goal is to meet the domestic demand. The ultimate goal of the project is to gain a small share of the domestic market with the possibility of expansion in the following years.

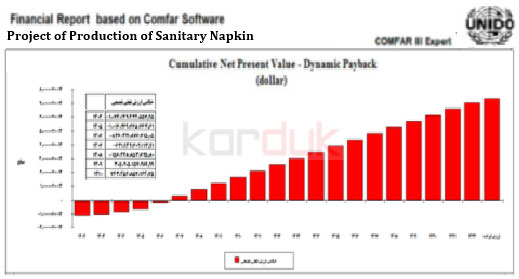

Financial Projection| Pre-Feasibility study of Production of Sanitary Napkin

The financial statements and operating costs of re-refining show a suitable situation for the project, considering the cost price of the products and the annual profit. The results of the analysis performed by the Comfar software, with a discount rate of 25%, also show an acceptable situation in terms of financial and economic terms for the base of Sanitary Napkin project with a capacity of 900 tons per year.

Summary of study Results

Production calculations show that the proposed production capacity can be increased according to the needs of the domestic market and the country, considering the competitive price of the products The financial statements and operating costs of sanitary napkin production show a suitable situation for the project, considering the cost price of the products and the annual profit. The results of the analyses conducted by Comfar software with a discount rate of 25% also show an acceptable situation in terms of financial and economic terms for the sanitary napkin production project with a capacity of 900 tons per year.

For more information about the Feasibility Studies of production Sanitary Napkin . you can contact Karduk.INC via WhatsApp, Telegram or E-mail.

Phone: +982166418908

Email: karduuk@gmail.com