Pre-Feasibility study of Autoclave Aerated Concrete (AAC) Blocks

In Pre-Feasibility study of Autoclave Aerated Concrete (AAC) Blocks the Technical, Financial, and Economic aspects of the project are explained.

Autoclave Aerated Concrete (AAC) or Autoclave Aerated Concrete is a high‐tech concrete which was innovated in the first decade of the In the 20th century, by adding aluminum powder and cement to a mixture of lime and silica, it was invented to produce porous and very light concrete. At first, it did not have sufficient strength, but after numerous studies and experiments, it was determined that if the concrete was cured at high temperatures and pressures, porous and very resistant concrete was obtained. Which can act as insulation due to the presence of gas bubbles within the concrete.

Technical Specifications| Pre-Feasibility Studies of Autoclave Aerated Concrete (AAC) Blocks

AAC blocks have high resistance for use in walls and ceilings and are also resistant to moisture and corrosives.

- These blocks are very good sound insulators due to their air-entrapped holes and are classified as good sound insulators according to the ASTM standard. A lightweight phenomenon in the housing industry and energy saving used as interior and exterior walls and partitions.

- Reduction in the cost of the execution team members by one-fifth of a brick and one-quarter of a tile

- Reduction in the dead load of the structure by one-quarter of a brick and one-third of a tile

- Reducing the dead weight of the structure by a quarter of bricks and a third of tiles

- Reducing mortar consumption by 30 to 50% of bricks and tiles

- Excellent performance in drilling and sawing and installing external equipment due to its integrated structure

- Reduction in the size of HVAC installations installed in buildings built with this product compared to other products.

- High resistance to fire and direct flames

- Finally, working with aerated lightweight concrete is simple and the speed of construction operations is 2 to 3 times faster than bricks and tiles due to its size and ease of use.

Alternative products |Pre-Feasibility Studies of Autoclave Aerated Concrete (AAC) Blocks

Several products are alternatives to aerated lightweight concrete, including CLC blocks, Balika lightweight concrete and lightweight concrete with perlite, Itong , Siporex and Cement blocks that have a high weight, while the other products mentioned can compete with ACC.

Application of AAC

The largest consumption of lightweight aerated concrete products is in the housing and construction industry. It can be used in civil engineering and structural installations of factories and industrial workshops, agricultural and livestock product processing enterprises, and these products are also used in reinforced form in construction and infrastructure projects.

The ISIC code of product| Pre-Feasibility Studies of Autoclave Aerated Concrete (AAC) Blocks

The International Standard Industrial Classification of All Economic Activities (ISIC) is the international reference classification of productive activities. Its main purpose is to provide a set of activity categories that can be utilized for the collection and reporting of statistics according to such activities. According to the ISIC classification system, the ISIC code (2935) is related to the production of various lightweight concrete products. And the ISIC code of the products of this plan is as follows

- Reinforced lightweight aerated concrete ceiling : 2695512329

- Wall blocks made of aerated concrete: 2695612327

- Unreinforced ceiling block made of aerated lightweight concrete: 2695612328

- Other unreinforced concrete products made of aerated lightweight concrete: 12695512366

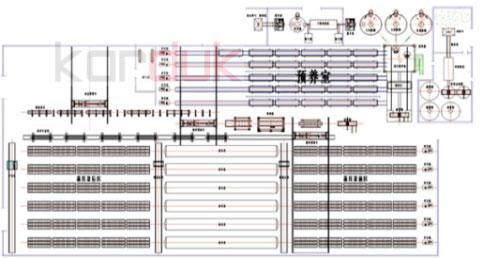

Buildings required for the project implementation

The building space required for the production, administrative and headquarters departments, according to the site plan and layout of production Autoclave Aerated Concrete Blocks, is as follows:

- Industrial production area 2,700 Mr2

- Warehouse of raw materials , products and spare parts store 900 Mr2

- laboratory: 70 Mr2

- Office (Administrative building): 100 Mr2

- Welfare building: 120 Mr2

- Mechanical and Electrical facilities and boilers : 150 Mr2

- Guard and weighing machine: 50 Mr2

- Weighing raw materials : 50 Mr2

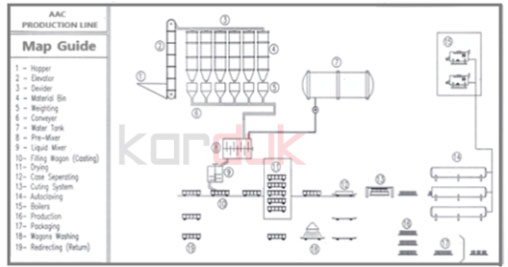

Autoclaved Aerated Concrete (AAC) block production process

In the production process, the main raw materials for the production of aerated lightweight concrete, including lime, silica powder, cement, and machine, are transported to the lime clinker production site by a feeder to a crusher and hammer mill, and after grinding, they are transferred to the micronized powder silos by a conveyor belt and and elevator.

After being stored in a silo, the silica powder is transferred to a ball mill to produce a wet slurry. After mixing and homogenizing, it is mixed with a dry and controlled mixture of cement and lime powder to form the final mixture, and the final slurry of aerated lightweight concrete is prepared with a mixer. In the next stage of the production process, the concentration and quality of the formulation and the amount of aluminum powder in the final mixture are checked, then this mixture is poured into prepared molds.

The concrete becomes bulky due to the reactions and after a few hours in the hothouse and fermentation, it is ready to be unloaded from the mold and cut horizontally and vertically according to market needs and planning.

After spacing, the cut pieces are transferred to autoclaves with a pressure of 12 atmospheres at 200 degrees for ten hours for final curing by special vacuums. After autoclaving, the products are ready to be transferred to the warehouse and packaged. It should be noted that all these processes have PLC control, industrial automation, monitoring, and a process control center.

Raw materials, auxiliary materials and packaging

For the production of AAC aerated concrete, the raw materials include lime, cement, silica, and water. The main raw materials for the production of AAC products do not pose any particular environmental problems, and these materials can be supplied entirely within the province. Equipment and Machinery| Feasibility Studies of Autoclave Aerated Concrete (AAC) Light Concrete Blocks

The most important part of the production process is the selection of machinery, its characteristics, manufacturing technology, production capacity, purchase, and installation and commissioning. The purchase of machinery is carried out through a thorough examination of technical and manufacturing materials. The specifications of the ACC lightweight aerated concrete production sections for a production capacity of 300 tons per day are:

- Storage section and lime crushing machinery

- Silica preparation machinery, grinding and slurry making

- Raw material storage silos

- Weighing, mixer, slurry casting equipment

- Block molds, traction system. Overhead crane

- Cutting line machinery

- Autoclave, boiler

- Production hall rail laying

For information on the technical specifications of the autoclaved aerated concrete production line machinery and facilities In accordance with the following processes please contact us.

- Raw material silos

- Balance and cut material feeder

- Raw material mixing

- Batch processing and preparation for the mold

- Molding

- Pre-treatment

- Semi-finished product rotation

- Demoulding

- Horizontal cutting

- vertical cutting

- Labeling and marking

- Block loading into the autoclave

- High temperature and pressure curing

- Block unloading from the autoclave

- Plate separation

- Horizontal cutting

- Vertical cutting

- Labeling and marking

- Loading blocks into autoclave

- High temperature and pressure curing

Introduce Target Market

Currently, there is a suitable demand for the product in the country and the added value of producing AAC products is suitable. The main target market of this project, technically and economically, at the national level, using modern marketing methods and networks, in the first stage is to meet the needs of the province, which does not have a share in the production of these products. The goal of the plan is to gain a one percent share of the domestic market with the possibility of exporting from the second year of production.

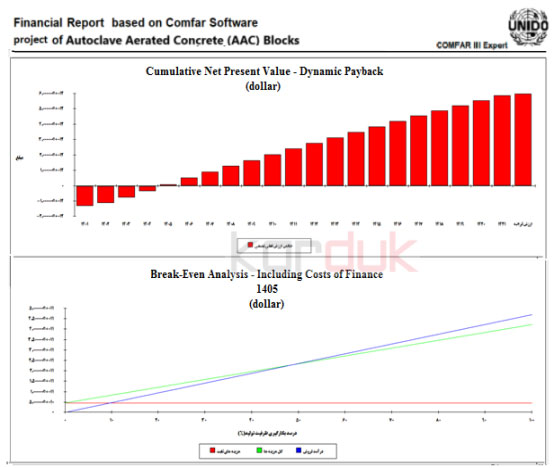

Financial Projection| Pre-Feasibility Studies of Autoclave Aerated Concrete (AAC) Blocks

The financial statements and operating costs of re-refining show a suitable situation for the project, considering the cost price of the products and the annual profit. The results of the analysis performed by the Comfar software, with a discount rate of 25%, also show an acceptable situation in terms of financial and economic terms for the Autoclave Aerated Concrete (AAC) Blocks project with a capacity of 90000 tons per year.

Dynamic Pay Back Period (DPBP)

Comfar’s calculations show that the normal capital return period will be three years and the moving cumulative capital return period of the project will be four years with the application of a discount rate of 25 % on costs and revenues.

Break-Even Analysis

Given the conducted financial calculations, the break-even value is 20.6%. Other cases related to the break-even analysis are presented in the table below.

Summary of study Results:

Production calculations show that the proposed production capacity can be increased according to the size of the market and the province, due to quality and competitive price. More than a decade of executive experience in construction and effective communication with the sales market network can guarantee the success of this activity

For more information about the Feasibility Studies of Autoclaved Aerated Concrete (AAC) block. you can contact Karduk.INC via WhatsApp, Telegram or E-mail.

Phone: +982166418908

Email: karduuk@gmail.com