Feasibility Studies of Production fruit juices

In Feasibility Studies of Production fruit juices the Technical, Financial, and Economic aspects of the project are explained.

Project description

All kinds of fruit juices can be produced in the factory with industrial machines. Juices are liquids that are naturally extracted from fruits or vegetables. Juice is made by squeezing fruits and vegetables or soaking them without using heat or any solvents. In some cases, fruit juice is made from concentrated fruit extracts.

This unit uses ready-made fruit concentrate to produce products. Concentrate means concentrated natural fruit juice. The reason for converting fruit juice into concentrate and then converting it back into juices that are available to the consumer is the ease of storing the concentrate due to its smaller volume compared to juice.

Usually, the fiber or pulp of the fruit is removed from the juices that are sold in the market. However, sometimes fresh orange juice with pulp or with small pieces of fruit is available in the market. Sometimes the juice is thick, sometimes it is frozen, and sometimes the consumer has to add some water to the juice to restore its natural consistency.

The most consumable types of juices include apple juice, orange juice, grapefruit juice, pineapple juice, tomatoes juice, mangoes juice, carrots juice and grapes juice.

Products of project |Feasibility Studies of Production fruit juices

The products of this plan are produced in weights ranging from 200 grams to one liter of pasteurized juice along with concentrated syrup in Doypack form of one to four liters.

Main products of this project are fruit juices (nectars) of various fruits including apples, grapes, peaches, apricots, strawberries, pomegranates, cherries and sour cherries and their concentrated syrups.

The characteristics of fruit juice concentrate, which is used as a raw material, are transparency, absence of impurities and higher bulk density than fruit juice. Its Brix is usually between 70 and 72.

Currently, fruit drinks are marketed in glass bottles, metal, polymer, cardboard, and multi-layer aluminum packaging in various flavors and names.

Products Categories

According to the standard, fruit drinks are divided into three categories:

- Juice: A product obtained with 100% juice content and can be prepared by squeezing fruit or natural fruit puree or diluting concentrated fruit juice (concentrate) with drinking water to the desired concentration.

In the case of sour fruits such as cherries and pomegranates, sugar can also be part of the formulation.

- Nectar: Obtained from a mixture of natural fruit juices or, alternatively, fruit concentrate or puree (puree is actually the crushed fleshy part of the fruit after separating its core, stem, and skin) with water, sugar, and other permitted additives (edible acid). This product has a lower percentage of fruit extract than fruit juice, and the minimum amount of fruit extract in it varies between 30 and 50 percent, depending on the type of fruit.

- Non-carbonated fruit drinks: This product contains at least 20% fruit extract or alternatively concentrate and water, and contains other ingredients such as sugar, edible acid, flavoring and natural food coloring.

Access to the Infrastructures| Feasibility Studies of Production fruit juices

The location of the project in the food industry zone of the industrial town provides the possibility of supplying water, electricity and gas based on the factory’s production needs. Location of the industrial town also provides access to main communication roads for supplying raw materials and selling products.

The Benefits of various fruit juices and syrups

Fruit is one of the main and important sources of vitamins, minerals, proteins, fiber, energy and other nutrients that the human body needs. Therefore, consuming fresh fruit, syrup and juice is essential in the human diet.

The problem with fruits is their long-term storage during seasons when fresh fruit is not available. On the other hand, the way fruits are consumed is also a market expectation that provides the conditions to meet the needs of a wide range of people’s taste.

Nowadays, people prefer to mix and consume juices from different fruits. Therefore, sales of juices made with only one fruit are much lower than those made with a combination of several fruits.

By creating different flavors and reducing some of the undesirable effects of consumption on a group of people, more appropriate and pleasant consumption is also provided.

Fruit juices are healthy and nutritious drinks rich in vitamins, minerals, and plant pigments that provide part of the body’s need for these substances. For example, grapefruit and oranges contain a lot of vitamin C. Carrot juice contains a lot of vitamin A in the form of beta-carotene. Fruit juices are an excellent source of essential minerals such as iron, copper, potassium, sodium, iodine, and magnesium. Citrus fruits help the body absorb iron, and drinking juices with red pigments reduces the risk of heart disease due to their antioxidants.

Product standard review| Feasibility Studies of Production fruit juices

The National Institute of Standards and Industrial Research develops numerous standards for various industries based on global standards. Development of standards is done to raise the quality level of domestic goods, help improve production methods and increase efficiency in industries, and monitor the implementation of mandatory quality control criteria for goods.

- Fruit nectars and carbonated fruit drinks – Characteristics and test methods Standard No.: 14345

- Fruits and their products – peach, apricot, pear, red plum, yellow plum, apple and kiwi purees – characteristics and test methods Standard No.: 11692

- Microbial characteristics of pressed fruit juices in aseptic and non-aseptic packaging – characteristics and test method : 6332

- Properties of concentrated apple juice – Properties : 2687

- Concentrated grape juice – features : 2615

- Concentrates and juices – Energy consumption criteria in production processes : 16748

- Apple puree – characteristics and test methods No.: 5210

- Peach-Plum-Pear-Apple and Apricot Nectars – Features : 2613

- Purees, pulps, seeds and pieces of fruits and vegetables (in water, syrup or fruit juice) – Characteristics and microbiological test methods No.: 19336

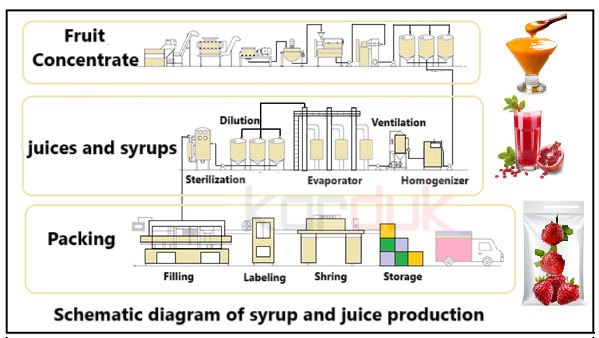

process of Production| Feasibility Studies of Production fruit juices

-

Mixing section

Depending on the type of juice, fruit nectar or fruit syrup concentrate must be mixed with some water, aroma, sugar and acid. To prepare fruit juice, the concentrate with the initial Brix is diluted with mineral-free, potable water. Some sugar is also added to sour cherry juice, which has a higher acidity. In the preparation of fruit nectar, the proportion of fruit juice in apples and grapes is at least 50%, and pears 35%, in cherries and pomegranates 30%.

The amount of concentrate should be calculated taking these values into account. Then amount of sugar added should be such that the final dry matter content in the nectar is 13%. If the acidity of the concentrate is lower than required, some acid (citric, malic or tartaric) should be added to the mixture.

In addition, aroma materials should be added taking into account the amount of natural fruit juice. Sugar is also added directly or in a solution with a concentration of 65%. product is prepared with hot water. For syrup production, the proportion of natural fruit in apples and grapes is at least 30%, in citrus fruits 6% and in other fruits 10%.

The dry matter content used in non-carbonated fruit juices is at least 11%. To prepare and blend the water, aroma, and acid, a tank with agitator is used.

-

Filtration

In order to separate the suspended solids from the water and sugar, the prepared fruit juice is finally passed through a filter.

-

Ventilation

When the raw materials are mixed, some air is also dissolved in the juice. In order to prevent oxidative changes, the juice is passed through an aerator to remove as much air as possible. This system, the juice is passed over the surface of the cylinder as a thin film and the air inside is removed under vacuum.

-

filling

In this process, pasteurization is performed after the filling of the packages, so the fruit juice is filled at 60 degrees Celsius.

Doypack bags are used for filling, and a vacuum system that operates automatically based on pressure balance is used.

-

Cooling

Then hot filling and pasteurization, the juice is cooled to 30-35°C. This is important both for microbiological stability and for preserving the taste quality.

If the bottles are left to cool, it will take a long time, which will cause undesirable changes in the taste and color of the juice

-

Product storage

After labeling and packaging in cartons, it is best to store the juices in a quarantine warehouse for 5 days. This will increase the speed of inversion and create a balance in the flavor of the juice

The ISIC code of product| Feasibility Studies of Production fruit juices

International Standard Industrial Classification of All Economic Activities (ISIC) is the international reference classification of productive activities.

Its main purpose is to provide a set of activity categories that can be utilized for the collection and reporting of statistics according to such activities. The ISIC code of the products of this plan is as follows:

- Pas non-citrus fruit juices from fresh fruit (not produced from concentrate): 1513412559

- Types of citrus fruit juices from concentrate: 1513412469

- Non-citrus syrups: 1513512519

- Types of citrus syrups: 1513412469

Alternative products

Fruit consumption is present in the household food basket in various forms. Some of it is in the form of fresh fruit, but in the industry, in order to create long-term storage capacity and also to create diverse flavors, various forms of fruits and vegetables are prepared.

In a situation where the market does not have access to fresh fruit , the existing forms of industrial products produced from various types of fruit will be available to the customer in the market, which will serve as substitutes for each other based on customer taste, as follows:

- Fresh fruit.

- Dried fruit.

- Fruit puree

- Frozen fruit.

- Various Canned fruits (jam, jelly, marmalade, compote, etc.).

- Fruit juice.

- Fruit syrup.

- Fruit desserts.

- Fruit pies.

Raw materials| Feasibility Studies of Production fruit juices

- Sugar

- Fruit concentrate – puree

- Citric acid

- Ascorbic acid

- Packaging plastic

- Die cut carton

- Doypack

Buildings required for the project implementation

The building space required for the production, administrative and headquarters departments, according to the site plan and layout of the production lines, is as follows:

- Production Building of juices and syrups: 703 Mr2

- Warehouse of products raw dry materials and spare parts: 300 Mr2

- Warehouse of raw dry materials and spare parts: 219 Mr2

- Facilities Building: 185 Mr2

- Lab and R&D Building: 50 Mr2

- Welfare and Office (Administrative building): 200 Mr2

- Security and janitor: 50 Mr2

whole process is controlled and monitored by plc.

Equipment and Machinery| Feasibility Studies of Production fruit juices

For this factory, most of the machinery is made of food-grade stainless steel. The required concentrate is obtained from another factory, and this unit only performs the step of converting the concentrate into fruit juice.

- Steam generator boiler (5 ton) 60 to 90 degrees

- CIP facilities

- Water purification system

- Fruit preparation section (washer, separator, slicer, shredder, pulper)

- Aseptic processing system

- Fruit juice preparation section (sugar scale, concentrate pump, concentrate storage tank, sugar melting tank, sugar syrup filter, mixing tank)

- Pasteurization and packaging (pasteurizer, water heater, packaging machine, cooling tunnel)

- Pipes and fittings

Juice line Equipment:

- steel processing tank 4250 liter

- steel mixing tank for preparing syrup and sugar in small batches

- Pasteurizer in small batches 2000 liter per hour

- Double pack machine with agitator and under feeder

- Cooling tunnel for juice in small batches 5 meter long

- Double pack filler with Spanish lid 200 cc to 1 liter

- Plastic pallets and baskets

- Steel conveyor belt for transferring bags from filler to cooler

- Vacuum Pump and ground pumps with electromotors

- Sugar discharge tanks with electromotors 2 kilowatt

- Z-lift with 2 kilowatts

- Twin steel filters 2 kilowatts

- Steel pump 4 kilowatt

Syrup production line Equipment

- Steel sugar discharge tank

- Z-lift, steel mixer with paddle mixer 4250 liters

- Steel filter and twin filter

- Syrup pasteurizer

- Steel tank for mixer 150 liters 4 kW

- Pectin filter

- Steel syrup storage tank with mixer and steam heating 4250 liters 3 kW

- All-steel deaerator

- CT mono pump 5.5 kW

- Six nozzle filling machine 1 to 4 liters

- CIP system

- Hot water steel tank with steam coil and mixer 2000 liter

- Water storage steel tank with paddle steam coil 5000 liter

- 4 Steel pump

World Trade | Feasibility Studies of Production fruit juices

Recent years, per capita fruit juice consumption in the country has reached about 10 to 15 liters, which is much lower compared to European and American countries.

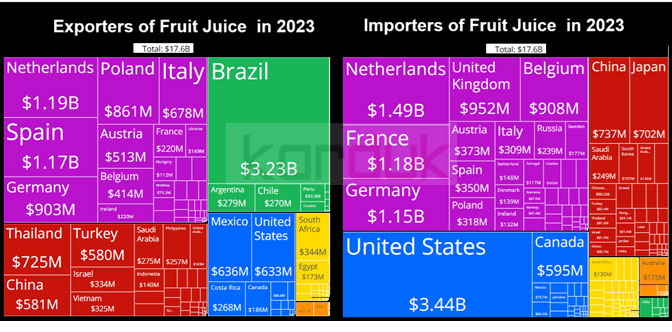

Global trade of Fruit Juice reached $17.6B In 2023, reflecting a 2.88% increase from 2022, when trade totaled $17.1B. Over the past five years, trade in this category has grown at an annualized rate of 0.82%.

Among the 1217 products traded in 2023, Fruit Juice ranked 227 in global trade value, accounting for 0.078% of world trade. According to the Product Complexity Index (PCI), It was the 808th most complex product out of 1044, with a PCI value of -0.82.

Exports and Imports

In 2023, the leading exporters of Fruit Juice were Brazil ($3.23B), Netherlands ($1.19B), and Spain ($1.17B). The top importers were United States ($3.44B), Netherlands ($1.49B), and France ($1.18B).

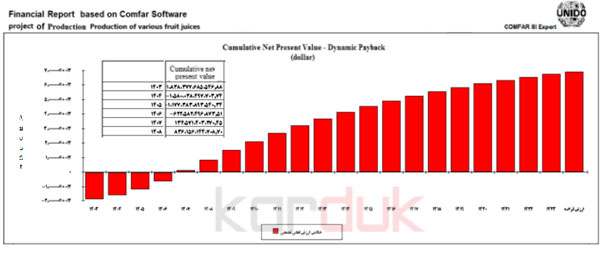

Financial Projection| Feasibility Studies of Production fruit juices

In this chapter, the financial and economic graphs of fixed and circulating capital, as well as operational costs of production are shown.

According to the finished price of the products and the annual profit of the production as well as the examination of the results performed by the COMFAR software , this project has an acceptable status from the point of view of expertise, and it is reliable from the financial point of view, The obtained output results does not show any important specific weakness for Production of various fruit juices and fruit syrups.

Product Sales Ratio

The largest sales volume is allocated to the production of various types of fruit juices and then fruit syrups due to the high price of raw materials. It is obvious that the annual price increase rate is applied during the production period with a capacity of 5000 tons per year and based on the discount rate.

Dynamic Pay Back Period (DPBP)

Comfar’s calculations show that the normal capital return period will be three years and the moving cumulative capital return period of the project will be four years with the application of a discount rate of 25 % on costs and revenues.

Summary of Study Results| Feasibility Studies of Production fruit juices

- The proposed Capacity of Production Margarine and Pasteurized butter in Relation to the Size of the Marker and Province can be Increased due to the higher Quality and Competitive Price of Products Compared to Domestic and Foreign competitors.

- Executive Experience of more than a Decade in the construction and effective communication with the distribution market network of the food industry as well as the lack of production fruit juice in the country production of pasteurized product in the country, can guarantee the success of this activity.

For more information about the Feasibility Studies of Production Margarine and Pasteurized Butter you can contact Karduk.INC via WhatsApp, Telegram or E-mail.

- Phone: +982166418908

Email: karduuk@gmail.com