Feasibility Studies of Production of Aquatic Feed

In Feasibility Studies of Feasibility Studies of Production of Aquatic Feed the Technical, Financial, and Economic aspects of the project are explained.

Project description:

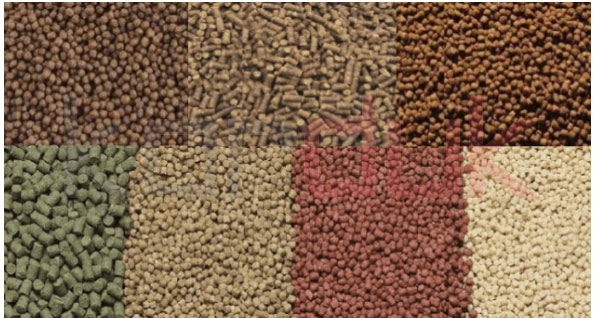

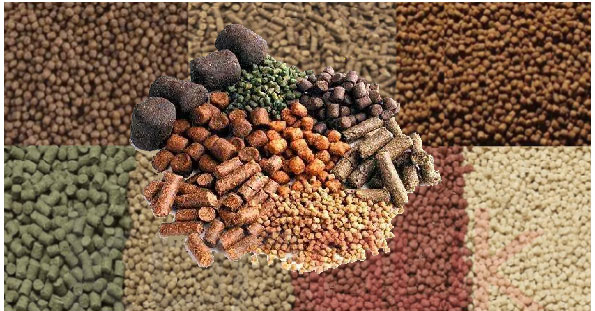

In fish and aquatic animal farming, in addition to the natural foods available in the pond, a complete food package is needed to meet their nutritional needs. Aquaculture feed is produced in three forms: dry, moist, and wet feed. which are distinguished by their moisture content.

Other ways of classifying feed include breaking them down into natural, supplementary, and complete feeds, or by life stage like starter, grower, and finisher feeds. Which during production process, the feed is first formulated in terms of its main ingredients including protein, fat, etc.

Project access status to infrastructure

-

Access to Water Resources

The province where this project is located has a relatively cold and temperate climate throughout the year, with more than 500 mm of rainfall, making it one of the most water-rich regions in the country, which also supplies the water needed for this project and fish farms through the river. It is also possible to supply the water needed for the aquatic feed production project.

-

Access to power supply infrastructure

Productive economic activities in aquaculture production depend on the supply of energy resources such as electricity. Therefore, access to energy and its cost play an important role in the economic justification of the project. The location of this project also has the possibility of accessing the required electricity.

-

Access to transportation infrastructure

The province’s land access roads are the main asphalt roads. This complex also has access to both the provincial center and neighboring provinces through the main roads to provide the necessary feed for the farms and aquaculture ponds.

-

Access to the telecommunication infrastructure

In the area where the aquaculture feed production project is located, there is no problem in accessing the telecommunications network and the Internet due to the development of the province’s telecommunications infrastructure.

Production of Project | Feasibility Studies of Production of Aquatic Feed

Aquatic food includes dry, wet and fresh feed. Dry feeds contain 7 to 13 percent of moisture. Their transportation and maintenance are relatively simple and can be easily distributed in large pools. Other benefits of such feeds include major purchases and maintenance, selection of different raw materials with special nutritional characteristics according to formulation ,easy quality control, low cost for food production , and higher productivity.

Dry aquatic food can be produced in different sizes and shapes, depending on the specific needs of each growth stage.

Also, dry food production is giving way to the production of food containing specific medications, such as various antibiotics to control the spread of diseases, or foods containing various types of hormones and additives to create single-sex fish or enhance growth and maturation in fish and shrimp.

Dried feeds can be prepared by using dry ingredients or a mixture of dry and wet materials that are properly processed and dried.

Dry feed can be produced in the form of flour, pellets, granules, laminates, etc. However, in rural areas, pellets are commonly used to feed aquatic animals.

Technical Specifications of Production of Aquatic Feed

Aquatic feed, due to its specific nutritional characteristics according to its formulation, which is slow-eating, must be produced in the form of pellets and crumbles. Currently, there are various methods for producing pellets, including pressurized or steam pellets and extruder pellets.

Press Pellet

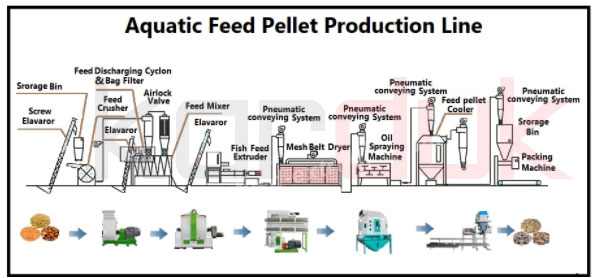

In the pressing method, the raw materials are first sieved and homogenized. Then, after being ground by a grinder and mixed by a mixer according to the adjusted diet formulation, they enter the cooking conditioner device.

In this machine, the moisture of the raw materials is removed by steam heat and the standard humidity level of production is maintained.

The raw materials, which have been sterilized by passing through the conditioner, enter the pellet press machine. In this machine, the materials are mixed and entered into the pellet press by the pressure of the rollers and are bonded and compressed by passing through the grid holes of the mold.

In this machine, the mixed materials are pressed. The agglomerated product passing through the die hole is cut and produced in the form of granules at the set length. As a result, in the pellet press production method, materials with low moisture and sterilization are mass-produced in the form of granules.

Extruder

In this method, the raw materials are fed into a polarizing mill for micronization. After screening and grinding, the fine-grained material is cut. Due to their small size, these materials can enter the capillaries of aquatic animals through the skin and saliva.

After grinding, the ingredients enter the mixer to be well mixed, homogenized, and then cooked. After cooking, the mixture is subjected to mechanical pressure in the extruder and is also subjected to thermal shock by the water vapor in the cylinder.

The product exiting the extruder is in the form of very hot granules containing large amounts of steam and moisture, so it must go through an initial drying stage. After adjusting the moisture, granulating and grading the product, it is fed into the vacuum coating machine with sieves.

This machine adds oil, lecithin, and liquid vitamins to the product under vacuum. After that, the product is cooled and sent to the packaging section.

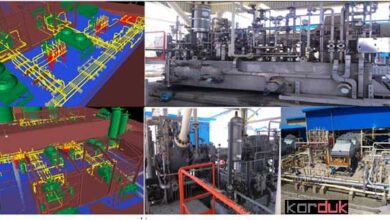

Equipment and Machinery | Feasibility Studies of Production of Aquatic Feed

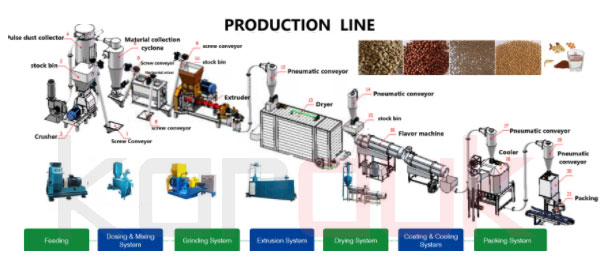

Technically, machinery and equipment for producing aquatic feed in the country are available at the appropriate technological level, and numerous engineering companies are developing aquatic feed production lines.

The Equipment required for Production of Aquatic Feed are as follows:

- Screening

- Storage tanks

- Weighing equipment

- Hammer Mill

- Horizontal mixer

- Polarizer Mill

- Crusher

- Mixer

- dust collector

- Double Conditioner

- Homogenizer

- Pneumatic conveyor

- Extruder

- Cutter Extruder

- Dryer

- Cyclones

- Radial fans

- Rotor Spray

- Dust filter

- Air compressors

- flavor machine

- Screw Conveyor

- Vacuum Coater

- Hydraulic Cooler

- heat exchanger system

- Packaging Machine

- Water Supply System

- Electricity and Fuel Network

- Diesel Generator

The purchase price of technical equipment and standard quality of machinery and equiment required for the production of aquatic feed, along with the price of office equipment, has been obtained.

Raw materials | Feasibility Studies of Production of Aquatic Feed

Raw materials and intermediate components for producing the product are as follow:

Grains flour, Fish Meal, Starch Soybean, meal Barley, flakes, Molasses, Lipid .

For more information contact karduk.inc

Application

Aquatic feed is used as one of the main consumables in fish and shrimp ponds and farms to feed aquatic animals in various forms.

The ISIC code of product| Feasibility Studies of Production of Aquatic Feed

The International Standard Industrial Classification of All Economic Activities (ISIC) is the international reference classification of productive activities. Its main purpose is to provide a set of activity categories that can be utilized for the collection and reporting of statistics according to such activities.

The ISIC code of the products of this plan is as follows:

Based on the ISIC classification system, the ISIC code (1533) is related to the manufacture of Aquatics ready to feed products and the project activity codes are presented as follows:

- Packing animal, poultry and aquatics feed: 15331110

- Prepared aquatic food: 15331120

- Aquatic food supplements: 15331121

Alternative products

Aquaculture units use supplements and prepared foods to feed aquatic animals, depending on the needs of the processes. Additives and their amounts may vary in different seasons. In general, there is no product that can be used as a substitute for prepared aquatic food.

Buildings required for the project implementation

The building space required for the production, administrative, and headquarters departments, according to the site plan and layout of the aquatic feed production unit, is as follows::

- Pools and production building 1000 Mr2

- Warehouse of raw materials, products and spare parts 250 Mr2

- Office (Administrative building) 100 Mr2

- Welfare building 300 Mr2

- Guard and weighing 50 Mr2

Market Vision

According to market studies and the shortage of aquatic feed commensurate with the province’s capacity of 12,000 tons and the country’s aquatic production capacity of 1,418,000 tons, the need for the product in provinces with aquaculture advantages is more important.

Financial Projection| Feasibility Studies of Production of Aquatic Feed

The financial statements and operating costs of the aquatic feed production plan show a favorable situation for this plan, considering the cost price, product sales capacity, and annual production profit.

The results of the analyses conducted with a discount rate of 25% also show an acceptable financial and economic situation for the aquaculture feed production plan with a capacity of 12,000 tons per year.

Summary of Study Results:

- The proposed capacity of aquaculture feed production is relative to the size of the market and the province, due to the high quality and competitive price of the products compared to domestic economic competitors.

- The founders’ more than a decade of executive experience in effectively communicating with the aquaculture feed market supply network due to the shortage of products in the country can lead to the success of this activity.

For more information about the Feasibility Studies Production of Aquatic Feed. you can contact Karduk.INC via WhatsApp, Telegram or E-mail.

- WhatsApp : +982166418908

- Email: karduuk@gmail.com