Feasibility Studies of Re-Refining Used Engine oil

in Feasibility Studies of Re-Refining Used Engine oil the Technical, Financial, and Economic aspects of the project are explained.

Project description

Lubrication is a method to prevent friction and abrasion of moving surfaces that come in contact with each other. Lubrication of equipment by providing suitable thermodynamic conditions working for movement industrial parts increases the useful life of parts and devices and reduces energy consumption and costs.

Therefore, the production of lubricants and industrial engine oils has a large important trade in the world. The production of industrial lubricants is very expensive and production has a short service life, so it is very profitable to recycle used oils that have expired and have caused a great deal of pollution to the environment.

Access status of Project to infrastructure

-

Access to Water Resources

The location of this project in a chemical industrial area with a temperate climate makes it possible to provide the required water supply.

-

Access to power supply infrastructure

Today, any economic activity relies on the supply of energy resources such as electricity and gas. Therefore, access to energy and its cost play an important role in the economic justification of the project. Considering the location of the project in an industrial district, it is possible to supply the electricity and gas required for the project.

-

Access to transportation infrastructure

The land access roads of the industrial town in the province are the main asphalt roads. This complex has access to both the provincial center and neighboring provinces via the main roads.

-

Access to the telecommunication infrastructure

Today, information and communication technology, telecommunications, and Internet infrastructure are of particular importance, and telecommunications infrastructure is available in the industrial area.

Technical Specifications | Feasibility Studies of Re-Refining Used Engine oil

Recycling Automotive used oil into Base Oil requires deep process knowledge. The final product of this industrial project is Refined engine oil (Base Oil). Automotive oil recycling involves the recycling process of used motor oils and hydraulic oil to creation new products such as base oils from them . Oil recycling also benefits the environment such as:

- increased opportunities for consumers,

- Increases the opportunity to reuse recycled oil

- reduce the possibility of oil spills on land and waterways.

One gallon of motor oil dumped into waterways has the potential to pollute thousands gallons of water. Used oil re-refining is the process of restoring used oil to new oil by removing chemical impurities, heavy metals and dirty materials. Used oil of automotive is recycled at refineries.

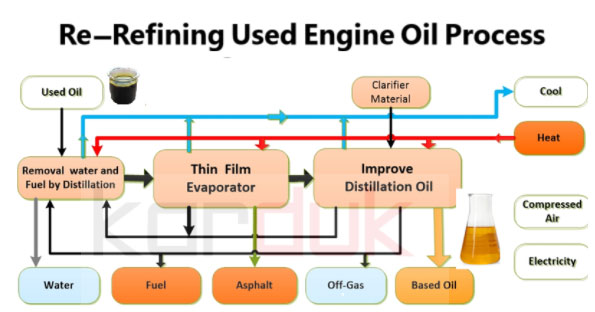

In the first step the used oil is tested to determine suitability for re-refining, then it is dehydrated, before being released into the environment.

In the first step the used oil is tested to determine suitability for re-refining, then it is dehydrated, before being released into the environment. Dehydrating also removes the residual light fuel that can be used to power in the refinery.

Next, industrial fuel is separated out of the used oil then vacuum distillation removes the lube cut leaving a heavy oil that contains the used oil’s additives and other by-products such as asphalt extender.

The lube cut next undergoes hydro treating, or catalytic hydrogenation in order to remove residual polymers and other chemical compounds, and saturate carbon chains with hydrogen for greater stability.

Final oil separation, or fractionating, separates the oil into three different oil grades include Light viscosity lubricants suitable for general lubricant applications, low viscosity lubricants for automotive and industrial applications, and high viscosity lubricants for heavy-duty applications.

The oil that is produced in this step is referred to as re-refined base oil (RRBL).

The final step is blending additives into these three grades of oil to produce final products with the right detergent and anti-friction qualities. During the process quality control is applied and in the final operation each product is quality control tested again for rate of purity according to standards , before being released for sale to the public

Alternative products | Feasibility Studies of Re-Refining Used Engine oil

Industrial oils produced by oil factories for use in engines and gearboxes are an alternative products for recycled base oils, but due to their high cost and environmental consequences, the use of recycled base oils is more justified

Application

Base oil is used as one of the main ingredients with a weight ratio of more than ninety percent in the production of various automotive oils and industrial oils for lubrication and friction reduction in industrial equipment and parts..

The ISIC code of product| Feasibility Studies of Re-Refining Used Engine oil

The International Standard Industrial Classification of All Economic Activities (ISIC) is the international reference classification of productive activities. Its main purpose is to provide a set of activity categories that can be utilized for the collection and reporting of statistics according to such activities.

Based on the ISIC classification system, the ISIC code (2320) is related to the manufacture of re-refined waste oil . And the ISIC code of the products of this plan is as follows:

- Waste oil refining: 23201240

- Hydrocarbons from refined oil: 23201245

- Types of re-refining lubricants; 2320312346

- Re-refined base oil: 2320412449

- Re-refined engine oil: 2320512353

- Re-refined industrial lubricating oils: 2320512356

- Re-refined turbine oil: 2320512354

- Re-refined gear oil: 2320512355

Buildings required for the project implementation

The building space required for the production, administrative and headquarters departments, according to the site plan and layout of the vehicle service center, is as follows:

- Industrial production area 700 Mr2

- Warehouse of raw materials , products and spare parts store 500 Mr2

- Oil testing laboratory: 50 Mr2

- Office (Administrative building): 100 Mr2

- Welfare building: 100 Mr2

- Waste oil pool: 200 Mr2

- Guard and weighing machine: 50 Mr2

- Electricity and gas station: 25 Mr2

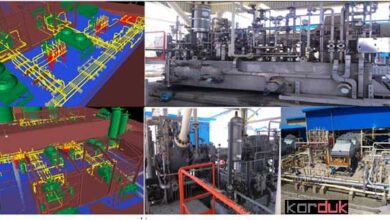

Equipment and Machinery| Feasibility Studies of Re-Refining Used Engine oil

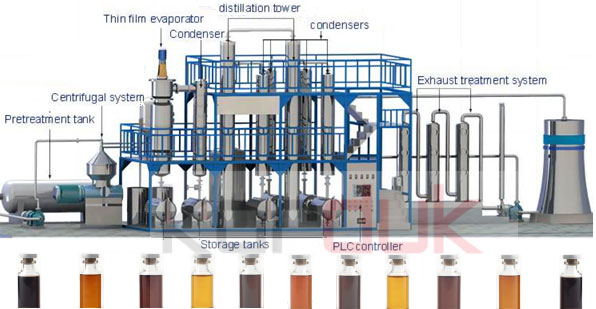

The Equipment required for the technical services of vehicles is as follows:

- Waste oil discharge tank

- Gear pump and valves and fittings

- Measuring tank

- Centrifugal pump

- Pre-treatment kettle

- Cooling tower pool pump

- Cooling tower

- Condenser

- Pre-treatment product receiver

- Vacuum pump

- Oil cooler

- Air compressor and penuatic tools

- Absorption Tower

- Absorption Tower Condenser

- Chiller

- Pretreatment Receiver Pump

- Vacuum Distillation Unit

- Double Basket Filter

- Vacuum Booster Pump System

- Three-Piece Receiver

- Hot Oil Boiler

- Demister

- Vertical Condenser

- Horizontal Condenser

- Large Receiver

- Vacuum Oil Cooler

- Boot Tank

- Pre Heater

The purchase price of technical equipment and standard quality machinery required for waste oil recycling has been taken along with the price of office equipment.

Raw Materials | Feasibility Studies of Re-Refining Used Engine oil

Raw materials include various types of lubricating oils and used engine oils, which are the output of passenger cars, industrial devices, aircraft, ships, etc., which are in urgent need of purification and prevention of environmental infiltration. This main raw material is collected by waste oil collection centers from oil changers and other relevant sectors and transported in bulk by tanker to the refinery site.

Introduce Target Market

The main sources of demand for industrial lubricants in the country are 33 million vehicles, industrial machinery and equipment and facilities in more than 70,000 industrial units.

Lubricants are used continuously in both moving old vehicles and new vehicles, and both in industrial and facility equipment. The base oil is converted into the final product in the factory by adding additives.

The need for continuous use of lubricants, along with the high price of first-refined base oils, has justified the increasing market demand and the tendency to invest in recycling used oils, which relies on both economic and environmental justification.

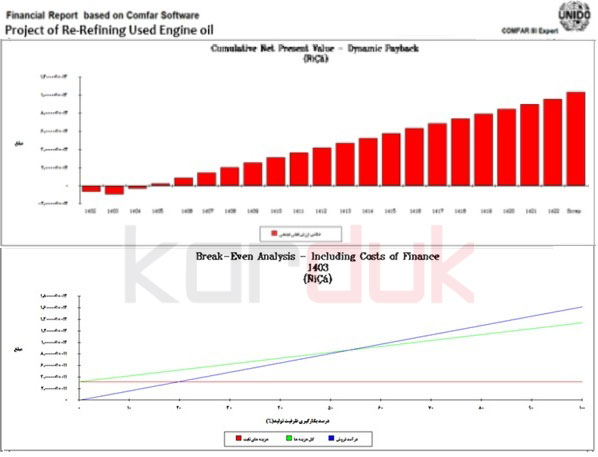

Financial Projection| Feasibility Studies of Re-Refining Used Engine oil

The financial statements and operating costs of re-refining show a suitable situation for the project, considering the cost price of the products and the annual profit. The results of the analysis performed by the Comfar software, with a discount rate of 25%, also show an acceptable situation in terms of financial and economic terms for the base oil recycling project with a capacity of 18,000 tons per year.

Dynamic Pay Back Period (DPBP)

Comfar’s calculations show that the normal capital return period will be three years and the moving cumulative capital return period of the project will be four years with the application of a discount rate of 25 % on costs and revenues.

Break-Even Analysis

Given the conducted financial calculations, the break-even value is 20.6%. Other cases related to the break-even analysis are presented in the table below

Summary of Study Results:

- The proposed Capacity of Re-Refining Used Engine oil in Relation to the Size of the Market and Province can be Increased due to the higher Quality and Competitive Price of products Compared to Domestic competitors.

- Executive Experience of more than a Decade in the construction and effective communication with the market network of the Sales Re-Refining Used Engine oil as well as the lack products in the country, can guarantee the success of this activity.

For more information about the Feasibility Studies of Re-Refining Used Engine oils. you can contact Karduk.INC via WhatsApp, Telegram or E-mail.

Phone: +982166418908

Email: karduuk@gmail.com